Fracking - An Unconventional Poisoning

Politics / Fracking Oct 12, 2013 - 02:26 AM GMTBy: Richard_Mills

Hydraulic fracturing, or fracking as it's more commonly referred to, is used to stimulate the production of oil and gas from unconventional oil and gas deposits - shales, coalbeds, and tight sands. These types of deposits need to be stimulated because they have a lower permeability than conventional reservoirs and require the additional stimulation for production.

Hydraulic fracturing, or fracking as it's more commonly referred to, is used to stimulate the production of oil and gas from unconventional oil and gas deposits - shales, coalbeds, and tight sands. These types of deposits need to be stimulated because they have a lower permeability than conventional reservoirs and require the additional stimulation for production.

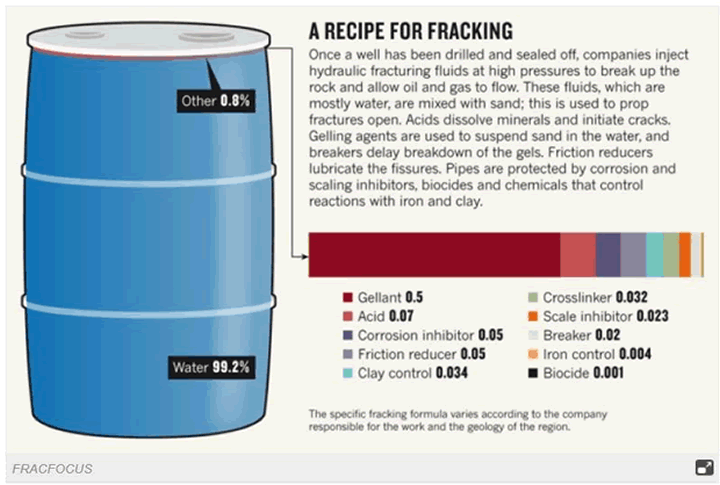

Hydraulic fracturing involves drilling a well then injecting it with a slurry of water, chemical additives and proppants. Wells are drilled and lined with a steel pipe that's cemented into place. A perforating gun is used to shoot small holes through the steel and cement into the shale. The highly pressurized fluid and proppant mixture injected into the well escapes and create cracks and fractures in the surrounding shale layers and that stimulates the flow of natural gas or oil. The proppants (grains of sand, ceramic, or sintered bauxite) prevent the fractures from closing when the injection is stopped and the pressure of the fluid is removed.

Proponents of hydraulic fracturing argue that fracking:

- Creates cheap domestic energy

- Replaces dirty coal-fired power plants

- Makes it easier to meet federal air and water quality standards

- Reduces our dependence on foreign supplied oil

"Fracture stimulation is a safe and environmentally sound practice based on the industry's decades-long track record, as well as the conclusions of government and industry studies and surveys." Halliburton, a major corporate proponent of fracking

Opponents of hydraulic fracturing have some serious concerns regarding:

- Contamination of the environment

- Threats to human health

- False promises of long-term economic benefits

Over the last several years there's been a dramatic rise in the use of hydraulic fracturing. As use of this technology has increased worries are growing about fracking's effect on our fresh water supply, it's easy to see why:

-

Fracking just one well can use two to eight million gallons of water with the major components being water (90%), sand or proppants (8-9.5%), and chemicals (0.5-2%). A four million gallon fracturing operation would use from 80 to 330 tons of chemicals and e ach well will be fracked numerous times.

-

Cracked wells and rock movement frequently leak fracking fluid and gases into nearby groundwater supplies. Fracturing fluid leakoff (loss of fracturing fluid from the fracture channel into the surrounding permeable rock) can exceed 70% of injected volume

-

Approximately 40,000 gallons of chemicals (including known carcinogens and toxins) are used per fracturing. Many of these chemicals have been linked to cancer, developmental defects, hormone disruption, and other conditions

-

Methane concentrations are 17x higher in drinking-water wells near fracturing sites than in normal wells. Hydraulic fracturing increases the permeability of shale beds, creating new flow paths and enhancing natural flow paths for gas leakage into aquifers

Here are a few excerpts from 'Myths Versus Realities...Getting the facts about Fracking' published by The Council of Canadians.

-

Research by the U.S. Environmental Protection Agency and the U.S. Endocrine Disruption Exchange Inc. has demonstrated that fracking fluids contain toxic substances known to cause serious health impacts such as cancer and organ damage, and can have negative impacts on neurological, reproductive and endocrine systems.

-

A 2011 study by the U.S. Environmental Protection Agency confirmed the clear link between fracking and water contamination.

-

Contamination of fracking fluids from one well to another - 'fracturing communication incidents' - has been documented in British Columbia. On May 20, 2010, the British Columbia Oil and Gas Commission (BC OGC) issued a safety advisory stating that they were aware of 18 fracturing communication incidents. The BC OGC's advisory also confirmed that fracking fluids can return to the ground surface, which poses a significant threat to water sources as chemicals could leach into nearby watersheds.

-

One study published in an academic journal by a professor at Cornell University suggests that fracked gas emissions may be worse than those associated with oil and coal.

-

In a recent briefing titled Health Implications of Fracking for Natural Gas in the Great Lakes-St. Lawrence River Basin, Dr. Theo Colborne noted that some workers were required to sign contracts preventing them from ever revealing their hourly wage or health problems. They were not even allowed to call 911 in case of an accident or a spill. Workers who suffered from hypertension, fibromyalgia, chemical sensitivity, memory loss and depression could not get worker's compensation because they could not prove their medical conditions were a result of chemical exposure.

As of 2010, it was estimated that 60 percent of all new oil and gas wells worldwide were being hydraulically fractured. As of 2012, 2.5 million hydraulic fracturing jobs have been performed on oil and gas wells worldwide, more than one million of them in the United States - Wikipedia.

The fracturing fluids job is to create the fractures, hold them open, place the proppants, and then lose viscosity to flow back up the wellbore. It has to do all that without damaging the reservoir. Typical fluid types are:

- Conventional linear gels. These gels are cellulose derivatives or guar (and its derivatives) based.

- Borate-crosslinked fluids are guar-based fluids cross-linked with boron ions. These gels are used to carry proppants.

- Organometallic-crosslinked fluids use zirconium, chromium, antimony, titanium salts to crosslink guar based gels. Gels are broken down with appropriate breakers.

- Aluminium phosphate-ester oil gels. Aluminium phosphate and ester oils are slurried to form cross-linked gel.

Fracturing fluid additives include: proppants, acids, gelling agents to thicken the fracturing fluid, gel breakers which allow fracturing fluid and gas to flow easily back to surface, bactericides, biocides, clay stabilizers, corrosion inhibitors, crosslinkers which help maintain viscosity of fracturing fluid, friction reducers, iron controls, scale inhibitors, and surfactants. The fracturing fluid will vary in composition depending on the type of fracturing used, the conditions of the specific well being fractured, and the water characteristics.

A typical fracture treatment uses between 3 and 12 additive chemicals to the fracturing fluid. The most often used chemical additives would include one or more of the following:

- Hydrochloric acid helps dissolve minerals and initiate cracks in the rock and is the single largest liquid component used in a fracturing fluid aside from water.

- Acetic acid is used in the pre-fracturing stage for cleaning the perforations and initiating fissure in the near-wellbore rock.

- Sodium chloride (salt) delays breakdown of the gel polymer chains.

- Polyacrylamide and other friction reducers minimize the friction between fluid and pipe.

- Ethylene glycol prevents formation of scale deposits in the pipe.

- Borate salts are used for maintaining fluid viscosity.

- Tetramethyl ammonium chloride prevents clays from swelling and shifting

- Sodium and potassium carbonates are used for maintaining effectiveness of the crosslinkers.

- Glutaraldehyde is used as a disinfectant of the water (bacteria elimination).

- Guar gum and other water-soluble gelling agents increases the viscosity of the fracturing fluid to more efficiently deliver the proppant into the formation.

- Formic acid and acetaldehyde are used for corrosion prevention.

- Isopropanol increases the viscosity of the fracture fluid.

- Methanol is a winterizing agent and product stabilizer

British Columbia's Vancouver Sun newspaper reported a well in Peace River North, British Columbia, Canada used more than 30 ingredients. These ingredients included hydrochloric acid, xylene (a central nervous system depressant), naphtha, polyethylene glycol and kerosene.

FracFocus.com

Each well uses between two and eight million gallons of locally-sourced freshwater which will be permanently contaminated by ground contaminants and toxic chemicals contained in the fracking fluid.

Hydraulic fracturing flowback not only contains chemicals added during well stimulation, but the water that flows out of the well as the gas is produced will contain a variety of toxic and carcinogenic substances, most of which are not contained in the fracturing additives. This is because chemicals and minerals are present in the shale zone formation water and they may be released during the hydraulic fracturing process. This release results in additional contaminates formed in the wastewater, ie bronopol is a biocide with low human toxicity that can release nitrite, which in alkaline medium reacts with secondary amines to produce the potent nitrosamine carcinogens.

The recovered waste fluid - water contaminated with chemicals and anything that water has come in contact with, meaning heavy metals and minerals - is often left in open air pits to evaporate, releasing harmful volatile organic compounds (VOC) into the atmosphere, creating contaminated air, acid rain, and ground level ozone.

Some of the recovered waste water is injected deep underground in oil and gas waste wells or even in saline aquifers, there are serious concerns about the ability of these caverns and aquifers to handle the increased pressure and in the U.S., evidence is showing that deep-well injecting is linked to the occurrence of earthquakes.

According to the industry's own numbers just 60-70% of the fracturing fluid is recovered, the remaining 30 to 40% of the toxic fluid stays in the ground and is not biodegradable.

No one is entirely sure what happens to the water that is not recovered from the fracking process but since the water returned to the surface contains radium and bromides we can be sure the lost water does as well.

"When bromide in the wastewater mixes with chlorine (often used at drinking water treatment plants), it produces trihalomethanes, chemicals that cause cancer and increase the risk of reproductive or developmental health problems."

The use of the large number of oxidants, particularly hydrogen peroxide, in the presence of bromide can produce compounds that are potentially carcinogenic.

Radium is a radioactive metal that can cause diseases like leukemia.

Benzene, toluene, xylenes, ethyl benzene, and a variety of other aromatic compounds are routinely used. Of these, benzene carries the greatest toxicity, due to its well-known carcinogenicity. These five compounds will tend to remain in water, and only be weakly absorbed.

From the Review of the DRAFT 'Supplemental Generic Environmental Impact Statement on the Oil, Gas and Solution Mining Regulatory Program

Toxicity and Exposure to Substances in Fracturing Fluids and in the Wastewater Associated with the Hydrocarbon-Bearing Shale' by Glenn Miller, Ph.D., Consulting Environmental Toxicologist to the Natural Resources Defense Council we get the following...

"The DSGEIS does not demonstrate that contaminants found in produced water and/or fracture treatment flowback water are safe for environmental or human exposure.

Thus, if drinking water were contaminated with as little as 0.1% of certain shale gas wastewater, it would constitute a violation of a drinking water standard. The small percentage of wastewater that can cause serious contamination supports an argument that effectively any contamination caused by shale gas wastewater would be considered unacceptable...

The flowback water (containing both the shale fracturing water and the produced water) that will carry contaminants from the shale and the fracturing additives is likely to be highly contaminated with metals, salts, and radioactivity that, in some cases, are greater than 1,000 times the drinking water standards. This level of contamination is sufficiently high that any level of contamination of surface and groundwater is unacceptable."

In 2005 U.S. President Bush, VP Cheney and Congress used a 2004 study (it said fracking posed no danger to drinking water, this study was conducted in an area where coal beds were being fractured, and not shale beds) by the Environmental Protection Agency (EPA) to justify legislation of the "Halliburton loophole," which exempts hydraulic fracturing from the Safe Drinking Water Act.

"Fracking for oil and gas embedded in shale rock basins across the country and world involves the injection of a 99.5-percent cocktail of water and fine-grained sillica sand into a well that drops under the groundwater table 6,000-10,000 feet and then another 6,000-10,000 feet horizontally. The other .5 percent consists of a mixture of chemicals injected into the well, proprietary information and a "trade secret" under the Energy Policy Act of 2005, which current President Barack Obama voted "yes" on as a Senator.

That loophole is referred to by many as the "Halliburton Loophole" because Dick Cheney had left his position as CEO of Halliburton - one of the largest oil and gas services corporations in the world - to become Vice President and convene the Energy Task Force. That Task Force consisted of the Secretaries of State, Treasury, Interior, Agriculture, Commerce, Transportation and Energy. One of its key actions was opening the floodgates for unfettered fracking nationwide.

Between 2001 and the bill's passage in 2005, the Task Force held over 300 meetings with oil and gas industry lobbyists and upper-level executives. The result was a slew of give-aways to the industry in this omnibus piece of legislation. On top of the "Halliburton Loophole," the bill also contains an exemption for fracking from Environmental Protection Agency (EPA) enforcement of the Clean Water Act and the Safe Drinking Water Act." ~ Steve Horn, desmogblog.com

What they exempted are ticking time bombs...

"The technology to recover natural gas depends on undisclosed types and amounts of toxic chemicals. A list of 944 products containing 632 chemicals used during natural gas operations was compiled. Literature searches were conducted to determine potential health effects of the 353 chemicals identified by Chemical Abstract Service (CAS) numbers. More than 75% of the chemicals could affect the skin, eyes, and other sensory organs, and the respiratory and gastrointestinal systems.

Approximately 40-50% could affect the brain/nervous system, immune and cardiovascular systems, and the kidneys; 37% could affect the endocrine system; and 25% could cause cancer and mutations.

These results indicate that many chemicals used during the fracturing and drilling stages of gas operations may have long-term health effects that are not immediately expressed. In addition, an example was provided of waste evaporation pit residuals that contained numerous chemicals on the CERCLA and EPCRA lists of hazardous substances." ~ Natural Gas Operations From A Public Health Perspecvtive, wv4mom.org

"The 14 leading hydraulic fracturing companies in the U.S. injected 10.2 million gallons of more than 650 products that contained chemicals that are known or possible human carcinogens, regulated under the Safe Drinking Water Act, or listed as hazardous air pollutants ." ~ 2011 congressional report on the chemicals used in hydraulic fracking

Is the shale revolution all it's fracked up to be?

"A New York Times investigation first unearthed major cracks in the 'shale boom' narrative in June 2011, finding that state geologists, industry lawyers and market analysts 'privately' questioned 'whether companies are intentionally, and even illegally, overstating the productivity of their wells and the size of their reserves.' According to the paper, 'the gas may not be as easy and cheap to extract from shale formations deep underground as the companies are saying, according to hundreds of industry e-mails and internal documents and an analysis of data from thousands of wells." Le Monde Diplomatique

"The economics of fracking are horrid. Drilling is destroying capital at an astonishing rate, and drillers are left with a mountain of debt just when decline rates are starting to wreak their havoc. To keep the decline rates from mucking up income statements, companies had to drill more and more, with new wells making up for the declining production of old wells. Alas, the scheme hit a wall, namely reality." ~ US financial journalist Wolf Richter, Business Insider

As companies pump out the fracking fluids bubbles and 'burps' of dissolved gas are released. These early gases are usually vented into the atmosphere for up to a month or more until the well hits full production, then it's hooked up to a pipeline.

Natural gas emits about half as much carbon dioxide as coal per unit of energy when burned but a report by Cornell University concluded that methane leakage was 3.6% to 7.9% of gas produced.

Natural gas is mostly methane (CH4), and methane is over 25 times (the Intergovernmental Panel on Climate Change (IPCC) says methane is 86 times more damaging than CO2 over a 20-year period) more efficient than carbon dioxide at trapping heat in the atmosphere over a 100 year period.

In August of 2013, a National Oceanic and Atmospheric Administration(NOAA) led study measured a stunning 6% to 12% methane leakage over one of the U.S.'s largest gas fields, the Uintah Basin, which produces about 1% of U.S. natural gas. Releases of those magnitudes could offset the environmental edge that natural gas is said to enjoy over other fossil fuels.

"Unless leakage rates for new methane can be kept below 2%, substituting gas for coal is not an effective means for reducing the magnitude of future climate change." Major 2011 study by the Center for Atmospheric Research (NCAR)

The new 'Proceedings of the National Academy of Sciences' study introduces the idea of technology warming potentials (TWPs) to reveal time-dependent tradeoffs inherent in a choice between alternative technologies.

In this new approach the potent warming effect of methane emissions undercuts the value of fuel switching. The switch from coal to gas, assuming a total methane leakage of 2.4%, would only reduce TWPs by about 25% over the first three decades - just half the oft touted 50% drop in CO2 emissions from the switch. The study found that if the total leakage exceeds 3.2%, gas becomes worse for the climate than coal.

The decline rate of shale gas wells is very steep. A year after coming on-stream production can drop to 20-40 percent of the original level. If the best prospects were developed first, and they were, subsequent drilling will take place on increasingly less favorable prospects. Try to imagine how much drilling is taking place just to keep even with the existing production rate, how about increasing production?

Here's James Howard Kunstler, author of "The Long Emergency" and his take on the situation;

"In order to keep production up, the number of wells will have to continue increasing at a faster rate than previously. This is referred to as "the Red Queen syndrome" which alludes to the character in Alice in Wonderland who famously declared that she had to run faster and faster just to stay where she is."

Conclusion

There's no doubt hydraulic fracturing and horizontal drilling have tapped huge resources previously thought unrecoverable. By the end of the year, the US will be producing more oil and gas than any other country in the world. And it's almost all thanks to fracking.

But at what cost?

Hydraulic fracturing of oil and gas wells is contaminating our fresh water supply. Wells are counted by the hundreds of thousands in the U.S. and Canada, millions have been fracked worldwide and we're drilling hundreds more per day. Each and everyone a potential ticking time bomb of human cancers and mutation. In the end, when the shale boom goes bust, and it'll be much sooner than most think, we'll have to live with what's been done to our environment. In a few short years will we be able to rationalize, to justify the short term benefits from poisoning our most precious resource, our fresh water?

Hydraulic fracturing should be on all our radar screens. Is it on yours?

If not, maybe one should be.

By Richard (Rick) Mills

If you're interested in learning more about the junior resource and bio-med sectors please come and visit us at www.aheadoftheherd.com

Site membership is free. No credit card or personal information is asked for.

Richard is host of Aheadoftheherd.com and invests in the junior resource sector.

His articles have been published on over 400 websites, including:

Wall Street Journal, Market Oracle, USAToday, National Post, Stockhouse, Lewrockwell, Pinnacledigest, Uranium Miner, Beforeitsnews, SeekingAlpha, MontrealGazette, Casey Research, 24hgold, Vancouver Sun, CBSnews, SilverBearCafe, Infomine, Huffington Post, Mineweb, 321Gold, Kitco, Gold-Eagle, The Gold/Energy Reports, Calgary Herald, Resource Investor, Mining.com, Forbes, FNArena, Uraniumseek, Financial Sense, Goldseek, Dallasnews, Vantagewire, Resourceclips and the Association of Mining Analysts.

Copyright © 2013 Richard (Rick) Mills - All Rights Reserved

Legal Notice / Disclaimer: This document is not and should not be construed as an offer to sell or the solicitation of an offer to purchase or subscribe for any investment. Richard Mills has based this document on information obtained from sources he believes to be reliable but which has not been independently verified; Richard Mills makes no guarantee, representation or warranty and accepts no responsibility or liability as to its accuracy or completeness. Expressions of opinion are those of Richard Mills only and are subject to change without notice. Richard Mills assumes no warranty, liability or guarantee for the current relevance, correctness or completeness of any information provided within this Report and will not be held liable for the consequence of reliance upon any opinion or statement contained herein or any omission. Furthermore, I, Richard Mills, assume no liability for any direct or indirect loss or damage or, in particular, for lost profit, which you may incur as a result of the use and existence of the information provided within this Report.

Richard (Rick) Mills Archive |

© 2005-2022 http://www.MarketOracle.co.uk - The Market Oracle is a FREE Daily Financial Markets Analysis & Forecasting online publication.